To control diesel generator pollution, the National Green Tribunal and Central Pollution Control Board set a few parameters to run Genset in various metropolitan cities. As per the research data of the NGT, the running of diesel generators is one of the major causes of air pollution. However, the popularity of diesel engine generators due to the low fuel consumption feature makes them the most demanding power backup resource. However, the main disadvantage of Retrofit Emission Control Devices for diesel generators burns is that they can negatively impact fuel economy and CO2 emissions if not properly designed and installed. These are more harmful to the human body and are major causes of lung damage, respiratory problems, cancer pollutants, and toxic gases.

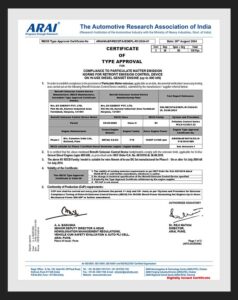

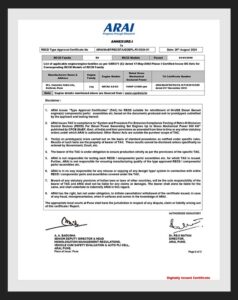

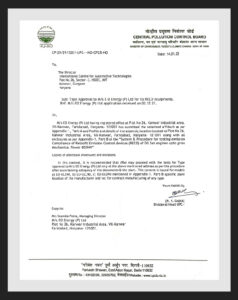

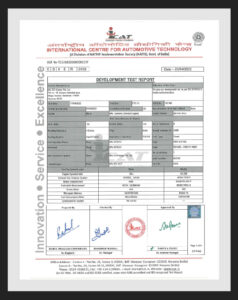

Keeping all these things in mind National Green Tribunal (NGT) issued a strict guideline (A copy of which we attached below) for the retrofitted emission equipment. At Eo Energy, we provide custom designs and retrofitted emission control systems to control hazardous gaseous pollutants emitted through diesel generators, following all the guidelines issued by NGT, CPCB & EPCA. We are the largest authorized distributor and manufacturer of Retrofit Emission Control Devices for DG Sets.

Retrofit Emission Control Device For DG Set

CPCB-certified RECD vendor for diesel generators up to 2500 kVA, Eo Energy is committed to providing innovative and effective solutions for reducing harmful emissions from diesel generators (DG Sets). As one of the leading manufacturers of CPCB-approved RECD for DG Sets, we offer a wide range of retrofitted emission control devices that meet stringent environmental regulations set by the Central Pollution Control Board (CPCB).

With a team of qualified technicians, we design and manufacture DG Set emission control devices for diesel generators up to 2500 kVA. Available units of retrofitted emission control devices designed to reduce particulate matter significantly, Nitrogen Oxide (NOx), and other pollutants, improving diesel engine performance and reducing operational cost. As a trusted partner, we provide comprehensive support, from product selection to installation and maintenance. Choose EO Energy CPCB-approved retrofitted emission control device for diesel generators for clean, reliable & environmentally responsible energy solutions.

Water

Resistance

Weather

Resistant

Stainless

Steel

Reduce

Pollution

Maintenance Free

Low

Cost

What is a Retro-fit Emission Control Devices (RECD)?

A retrofitted emission control device designed to reduce harmful emissions & pollutant particles from the diesel generator. This DG Set pollution control device is built on filter-less technology & by using electrostatic precipitation. This technique makes DG Set RECD more effective in enhancing air quality & diesel particulate capturing carbon matter with an efficiency of more than 90%.

The retrofit device technique adds extra gain to control the emission of hydrocarbons and carbon monoxide from diesel generators. The very common retrofitted technology for DG Set is equipment installation of retrofit devices in the diesel engine exhaust system. The retrofitted equipment installed in the exhaust system controls the emission during the diesel generator operation. These RECDs are built and tested to follow the standards of the National Green Tribunal (NGT), Central Pollution Control Board (CPCB), and Ministry of Environment, Forest and Climate Change (MoEF & CC).

Emission control device manufacturer & supplier in India- Choose the right emission control device for DG Set

Moreover, the Eo Energy RECD aligns perfectly with the guidelines set forth by the National Green Tribunal and Central Pollution Control Board. These pollution control devices can boost the reduction efficiency by more than 90% for Hydrocarbons (HC), Particulate Matter (PM), and carbon Monoxide (CO). This accomplishment has been validated & approved by Pollution Control Board-accredited labs to ensure compliance with stringent emission standards.

Here check the list of pollution control equipment for Genset based on its size & power output.

Availability of RECD kit for DG Set based on the Genest type & size offers the best buying opportunity to our precious clients. With years of technical experience & a team of experts, the goal is to achieve the highest level of performance. All our products follow the industrial standard norms to make your industrial generator more efficient & reliable. A few major beneficial functions of our service. To perceive the best product that matches your needs listed below,

- Product manufacturing is based on the needs of the application.

- Low buying cost of the retrofit emission control device.

- Testing in all parameters before RECD installation.

- Availability for both new and existing Genset.

- High-grade materials & super relative technology.

- Our services are designed to provide the best value for your investment.

How a retrofit device attached to diesel generators can reduce air pollution?

In our daily lives, diesel generators play an important role & reduce reliance on the power backup unit. Also, diesel Genset units are major resources to run industrial & commercial applications during planned or unplanned power failure. There are several benefits of having a diesel engine DG Set such as efficiency, cost-effectiveness, high torque & many more. But along with it, they emit harmful gases together with CO2, carbon monoxide, and others which are highly dangerous for our ecosystem.

To control harmful emissions of diesel Gensets, Eoenergy introduced a retrofitted emission control device for DG Set that helps to control the pollution particles from diesel generators, enhancing air quality and capturing carbon matter with an efficiency of more than 90%.

Retrofit emission control technology

The retrofitting of emission control devices is a filtration system that filters specific particles. The manufacturing design of this device is a stainless steel box that is hooked to the generator exhaust system, either as an original gadget or as a retrofit device. The device is designed to be energy-efficient, and robust. In some cases or with the particular device, they may be attached to the original muffler or silencer.

This diesel generator retrofit device is the best way for the proper treatment of pollution control. The device can be easy to install in existing or new diesel generators to control the PM, carbon monoxide, nitrogen oxide & other pollutants particles.

At Eo Energy, we prioritize our customers’ satisfaction and peace of mind. Thus, we provide a comprehensive solution package for our RECD, consisting of Pre-supply checks and Support, Supply and Installation, Testing and Handover.

The below reference table will help you to get a better understanding of the various norms of Genset emission.

| Emission Norms for Genset Engines | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Emission Norms | Category (KW) |

Date of Implementation |

Pollutants (g/KWh) |

Smoke | Test Cycle | Test Equipment | |||

| CO | HC | Nox | PM | m-1 | |||||

| CPCB - l | 0-19 | Implemented from 2003 - 2005 depending upon Power band | 3.5 | 1.3 | 9.2 | 0.3 | 0.7 | ISO 8178 D2-5 Mode Cycle | Steady State Dynamometer, Partial Flow SPC(PM), Raw Emission Measurement Systems. |

| > 19-36 | |||||||||

| 37 - 75 | |||||||||

| > 75 -129 | |||||||||

| 130 - 560 | |||||||||

| 561 - 800 | |||||||||

| CPCB- ll | 0-19 | Jul. 2014 | 3.5 | HC+Nox=7.5 | 0.3 | 0.7 | |||

| > 19-36 | HC+Nox=4.7 | 0.3 | |||||||

| 37 - 75 | |||||||||

| > 75 -129 | HC+Nox=4.0 | 0.2 | |||||||

| 130 - 560 | |||||||||

| 561 - 800 | |||||||||

DIESEL EMISSION REDUCTION TECHNIQUE

Way to Control Diesel Genset Pollution

Retrofit technique

The retrofit technique in diesel generators is the addition of a pollution control device to control the emission rate from the engine exhaust. This trusted technique to remove emissions is very effective & able to reduce more than 90% of pollutant particles in specific cases. The device is used for diesel retrofit along with nitrogen oxide catalysts, diesel oxidation catalysts, exhaust gas recirculation, diesel particulate filters & others.

Repower

Repowering the DG Set is a process where the owner will replace the existing engine with the new one to enhance efficiency and reduce emissions. This technique is more useful when you need to use your device for longer purposes. Repowering any old device gives the opportunity to install a new engine with the latest emission control features. This repower feature of retrofitted emission control devices makes them more useful during operations.

Rebuild

The routine maintenance & replacement of old or faulty parts are the best methods to get high efficiency from diesel engine devices. Also, the major maintenance provides an opportunity to rebuild the engine with a more modern technique, which can lead to significant improvements in performance. Modern engines emit less emission as compared to the old ones or we can say the rebuilt cleaner parts give immediate emission reduction benefits.

Refuel

There are various fuel types used in the generator. Some of them need a few modifications in the engine or some complete replacement. A few of the alternative fuels such as diesel, biodiesel, ethanol, gas, or propane are used as a supplementary addition to reducing emissions.

Replace

Retiring the higher-polluting diesel engine device is always the best method to control the pollution level in our ecosystem. So whenever the existing products didn’t match the standard emission level replacing them with newer, cleaner alternatives is a highly effective technique for reducing pollution.

Genset Emission Control Device List

| Product Name | Emission control device |

| Material | Stainless steel |

| Power | Based on the unit |

| Frequency | 50 Hz |

| Voltage | 430 V |

| Used in | Industrial diesel Genset |

1) Mild Steel emission control device

Suitable design with high efficiency the mild steel emission control device presents rugged & robust features for long-duration use. It is also able to tackle various types of emissions based on their level. Here is more specification detail.

2) A three-phase fugitive emission control device

This emission control device is used to recycle the pollutants particles which emit from the diesel engine. The improved emission filter method is also helpful in protecting the environmental ecosystem. Here get more inquiries with product details,

| Application | Industrial lead recycling plants |

| Phase | 3 Phase |

| Used in | Higher than 125 kVA DG Set |

| Capacity | 1200 CMH |

| Voltage | 410 V |

| Finishing | Paint coated |

Most Popular Emission Control Devices for Diesel Engine

Here is the list of the most popular & best emission control device for diesel engines.

Catalytic converter

The catalytic converter is an emission control equipment that converts toxic gases into a less harmful compound. It uses a chamber known as a catalyst to facilitate this conversion. A catalytic converter is placed in the exhaust system next to the engine and looks like a large metal box. It consists of pellets coated with a catalyst and an insulated chamber containing a honeycomb structure. The converter contains precious metals like platinum, palladium, and rhodium and a honeycomb structure.

PCV valve

PCV stands for positive crankcase ventilation. PCV is a one-way valve attached to the crankcase of an engine. The crankcase holds the motor oil and is located at the bottom of the engine. When the engine fuel burns, it produces gases. The device uses the engine vacuum to pull air through the crankcase and routes it back into the intake manifold. It burns the gases and fuel safely without harming the environment.

EGR valve

EGR or exhaust gas recirculation valve is used to reduce the formation of nitrogen oxide (NOx) emission. When the combustion chamber temperature exceeds 1370℃, it creates harmful gases like nitrogen and passes through the exhaust system to the atmosphere. The exhaust gas recirculation system helps to control the combustion temperature reduces the formation of NOx and releases more efficient exhaust.

Evaporative emission control

The Evaporative Emission Control (EVAP) system is designed to prevent fuel vapors from the fuel tank from escaping into the atmosphere. This is important to prevent the fuel vapor from getting vaporized because it contains various hydrocarbons and forms smog when it reacts to sunlight. It means if the fuel system opens it pollutes the environment for 24 hours. It is essential to have an EVAP system on our vehicles.

Air injection

An air injection system is an emission control device that forces fresh air into the exhaust ports of the engine to reduce carbon monoxide (CO) and hydrocarbons (HC) emissions. The exhaust gases can contain partially and unburned fuel. Injecting oxygen-rich air from the Air injection injects oxygen that causes this fuel to continue to burn and reduce the exhaustion of harmful gases like carbon monoxide and hydrocarbons.